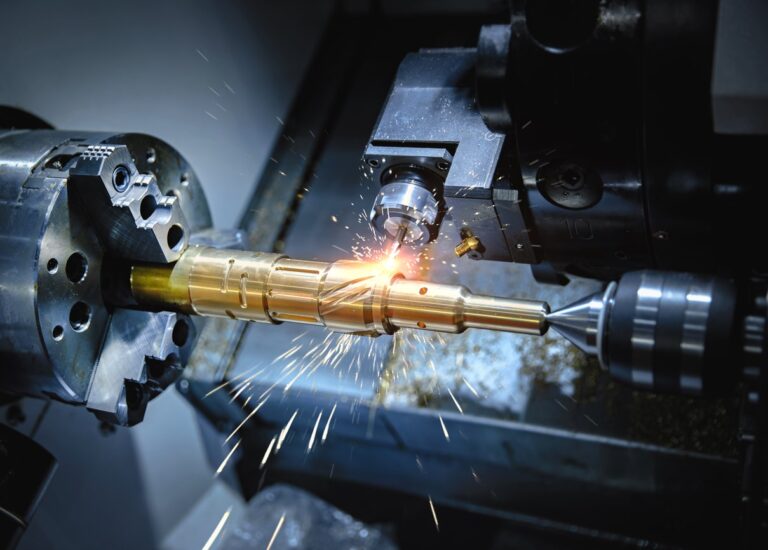

Computer Numerical Control (CNC) machining has revolutionized manufacturing by offering unmatched accuracy, efficiency, and repeatability. At the heart of this technology are CNC Machining Tools—specialized cutting instruments and attachments that enable machines to shape, drill, mill, and finish components with extreme precision. Whether producing aerospace components, automotive parts, or custom prototypes, the choice and quality of CNC tools directly affect productivity and product quality.

Understanding CNC Machining Tools

CNC machining tools are designed to remove material from a workpiece to achieve the desired shape and dimensions. Guided by computer programs, these tools perform tasks such as cutting, drilling, milling, and turning with minimal human intervention. Each tool is crafted for a specific function, material, and surface finish requirement.

Key advantages include:

- High Precision: Tools cut to tight tolerances, often within microns.

- Efficiency: CNC tools can operate continuously with minimal downtime.

- Versatility: They work on metals, plastics, composites, and more.

Main Categories of CNC Machining Tools

1. Milling Tools

Milling tools are perhaps the most common in CNC applications. They use rotary cutters to remove material and can produce flat surfaces, slots, or complex 3D contours. Common milling tools include:

- End Mills: Ideal for profiling, slotting, and contouring.

- Face Mills: Used for large, flat surfaces.

- Ball Nose Cutters: Perfect for sculpting complex curves.

2. Turning Tools

Turning tools are used in CNC lathes to shape cylindrical parts. These tools move along the rotating workpiece to create smooth, precise diameters.

- Boring Bars: For enlarging and finishing holes.

- Grooving Tools: For creating recesses or grooves in parts.

- Parting Tools: For cutting off finished pieces from raw material.

3. Drilling Tools

Drilling tools create precise holes in workpieces. CNC machines use a variety of drill bits, depending on hole size and material.

- Twist Drills: Standard for most drilling operations.

- Center Drills: For starting holes with accuracy.

- Step Drills: For making holes of different diameters in one pass.

4. Threading Tools

Threading tools are used to cut screw threads inside or outside a part.

- Taps: For internal threading.

- Dies: For external threading.

- Thread Mills: For creating threads using a milling process, offering more flexibility.

5. Grinding and Finishing Tools

Grinding wheels, abrasive discs, and polishing tools ensure surfaces meet required finishes and tolerances.

Material Selection for CNC Tools

The performance of CNC machining tools heavily depends on the materials used to manufacture them.

- High-Speed Steel (HSS): Cost-effective and suitable for general-purpose machining.

- Carbide: More durable than HSS, ideal for high-speed cutting and harder materials.

- Ceramics and Cermets: Best for high-temperature cutting and abrasive materials.

- Diamond-Coated Tools: Provide exceptional wear resistance for non-ferrous metals and composites.

Factors to Consider When Choosing CNC Machining Tools

1. Material of the Workpiece

Different materials require different cutting speeds, feed rates, and tool geometries.

2. Type of Operation

Milling, turning, drilling, and grinding all require specialized tool designs.

3. Precision Requirements

High-precision parts demand tools capable of holding tight tolerances.

4. Durability and Wear Resistance

Longer-lasting tools reduce downtime and increase productivity.

5. Cost Efficiency

Balancing tool cost with lifespan and performance is critical for profitability.

Modern Innovations in CNC Machining Tools

Advancements in CNC technology have led to the development of smart tools and coatings designed to improve performance:

- Coated Tools: Titanium nitride (TiN), titanium aluminum nitride (TiAlN), and diamond coatings improve tool life and heat resistance.

- Indexable Inserts: Allow quick replacement of cutting edges without changing the entire tool.

- Hybrid Tools: Combine multiple functions, such as milling and drilling, to save time.

Tool Maintenance and Management

Proper care of CNC tools is essential for maintaining precision and extending tool life:

- Regular Inspection: Check for wear, chipping, and thermal damage.

- Proper Storage: Keep tools clean, dry, and organized.

- Tool Tracking Systems: Many manufacturers use software to monitor tool usage, replacement schedules, and performance.

Industries That Rely on CNC Machining Tools

CNC machining tools are essential across numerous sectors:

- Aerospace: Precision components for aircraft engines and structures.

- Automotive: Engine parts, gears, and custom modifications.

- Medical Devices: Surgical instruments and prosthetics requiring high accuracy.

- Electronics: Small, complex parts for circuit boards and enclosures.

The Future of CNC Machining Tools

As automation and AI continue to advance, CNC machining tools are expected to become smarter and more adaptable:

- IoT-Enabled Tools: Real-time monitoring of tool wear and performance.

- Adaptive Machining: Tools that adjust parameters based on feedback during operation.

- Eco-Friendly Tooling: Sustainable materials and processes to reduce environmental impact.

Conclusion

CNC machining tools are the foundation of modern precision manufacturing. From milling and turning to drilling and finishing, each tool plays a vital role in shaping materials into functional, high-quality components. By understanding the different types, materials, and maintenance practices, manufacturers can maximize productivity, reduce costs, and deliver exceptional results.

Investing in the right CNC machining tools—and maintaining them properly—ensures long-term success in an increasingly competitive global market.